Find the best and top notch milk machine

The dairy business is flourishing at a fast pace. With that, it becomes essential for the business owner to select the equipment and machinery that stands out in terms of overall quality and is available at the right price. That’s the reason the selection of the best Dairy Equipment Manufacturers in India is crucial in every sense. So, from the start, get the expertise of the skilled team to make a choice easily.

Choosing the modern based milking machine

Whether your preference is to get the Khoya Making Machine, milking machine, or any other latest equipment, then it’s essential to choose something that stands out in different ways. Selecting the right options to make everything go on the right track. No doubt, it’s easier to select everything on your own; therefore, you need to trust the expertise of the professionals who are known names in the field for the last so many years.

The modern milking machine is much better in terms of quality as compared to manual milking. No doubt, the options are endless but get the expertise of a renowned manufacturer and supplier to make the selection easier. The expert team assistance makes the selection much easier on a regular basis.

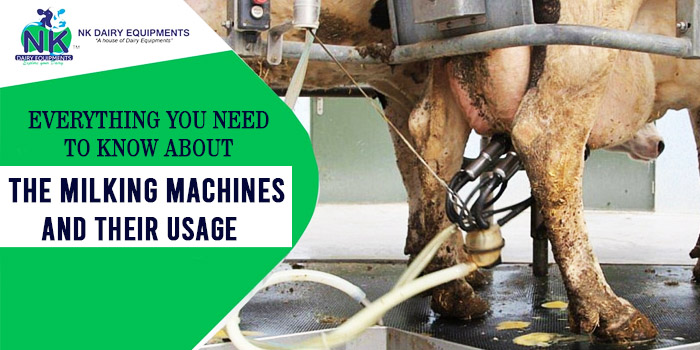

Look for different models and then ask the team

When you begin searching for the milking machine for the milk plant or any other machinery for Ghee Plant, explore the different models present over the net. Afterward, you need to choose the one that sticks to your business approach and will make a difference to overall dairy business productivity. So choose the selection of the milking machine through different factors like:

- Latest model with advanced technique

- Affordable price as you need to spend on other necessary chores

- Tell the dairy equipment manufacturer and supplier about the specific requirements. So this will make it much easier to select the most appropriate choice.

- Choose the technique that stands out as compared to all other models available in the market.

Are you confused about making the right selection?

No doubt, with affordability, comes the option of choosing something that stands out in terms of quality. If you are considerate about something and want to make an informed choice, then get the assistance of the renowned and skilled team of dairy equipment manufacturers to make the selection easier.

Nk Dairy Equipment manufacturers have years of expertise

The dairy business ever increasing demand gives the opportunity to the manufacturers and suppliers to up their game. Indeed! It’s an altogether different approach, and only the expert & skilled team can do it the right way. Indeed! It’s a journey, so you better do things the right way. If there’s any confusion on your mind, then feel free to ask about the same to the team and get the machinery at an economical price under your budget.