Gentle milking with higher throughput: AutoTandem milking parlor, NK Dairy Equipments and GEA meets the highest requirements of both cow comfort and efficiency.

This milking parlor is completely different from other parlors:

Economic, cost-effective and yet individual milking that’s just right for each cow is the most important factor when it comes to successful milk production. The dependable AutoTandem milking parlour by GEA Farm Technologies masters this challenge with its sophisticated technology, robust construction and a high level of automation.

AutoTandem:

the system that makes it easy to keep an eye on the milking process. The AutoTandem concept means more comfort for both the cow and the milker and is the premise for fast milking with first-class milking results:

• Cow-friendly dimensions of individual stalls

• Long-lasting, hot-dip galvanized construction

• Automatic control system for animal changeover

• Low-noise gates powered by vacuum cylinders • Clean and safe integration of all electronics, supply lines, and operating control panels

• Stall control system with reliable light sensors

Now there’s no need to wait for cows that are difficult to milk and slow down the entire milking process. Cow changeover in the individual stalls is controlled automatically by light sensors. It’s easy to keep an eye on the animals and, what’s more, they are more willing to be milked, which is the basis for calm and continuous cow change over.

AutoTandem:

The milker’s working conditions are improved because his work load is evenly spread and milking comfort is greatly enhanced. The cows enter and leave their milking stall on their own without any agitation, which means they remain placid and stress-free throughout the entire milking session. This, in turn, also makes the operator’s work more comfortable with higher throughput.

The variable milking parlour system

Without having to forgo any technical advantages when it comes to milking, the individual stalls can be arranged in all kinds of different layouts. L-shapes, U-shapes or onesided milking parlours can be set up to suit the building. This is what makes the AutoTandem concept so interesting for all herd sizes.

Precision Livestock Farming

To be better equipped for the future, the operator needs individual data on each cow. Milk yields and cow activity data – collected automatically – are an essential aid in health and reproduction management. GEA Farm Technologies DairyManagementSystem 21 will help you to keep ahead in herd management now and into the future.

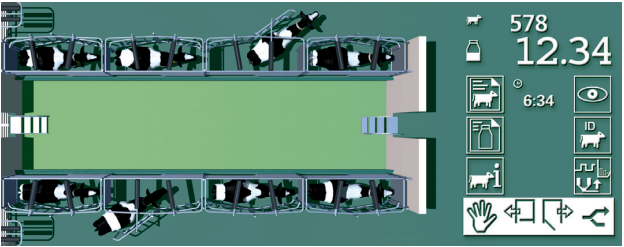

Metatron P21

All functions and displays can be entered rapidly and easily at the touch of a button, which means that Metatron can be individually matched to any milking operation. Metatron P21 optimises milking management perfectly with parallel displays of cow data in the form of graphics, symbols and exact figures. Metatron is not only highly userfriendly, it can also be placed in the best ergonomic position. The positioning and operation of the integrated DPNet gate control system make for fast group changeovers, and all who work with it will appreciate the uncomplicated and fast operating sequences while still retaining good body posture.

PosiLactor – positions and supports

Good positioning in a AutoTandem milking parlour goes without saying:

Benefits: