The iDURO is a high performance entry level rotary platform, making it a perfect option for those with shorter operating times.

The iDURO is a high performance entry level rotary platform, making it a perfect option for those with shorter operating times.Allowing for a seamless integration with all automation products and expert milking equipment the iDURO can grow with your business. A low maintenance cost effective system that will keep you running during your peak operating times. The solution starts with the platform and stalling to suit your needs, then the milking system and automation options are customised to suit your budget, ensuring your new solution is future proofed.

Designed with a single beam pedestal roller system under the platform coupled with the use of heavy duty nylon rollers, makes the iDURO an extremely low maintenance cost option.

The use of nylon rollers means no wear strip is required because there will be no wear from steel to steel contact. The system is fitted with an automatic lubrication system means there is no messy oil lubrication and ensures a long life and trouble free operation. A revolutionary compensator system ensures that all rollers sit perfectly flat on the beam and the weight of the platform is distributed evenly across all of the rollers.

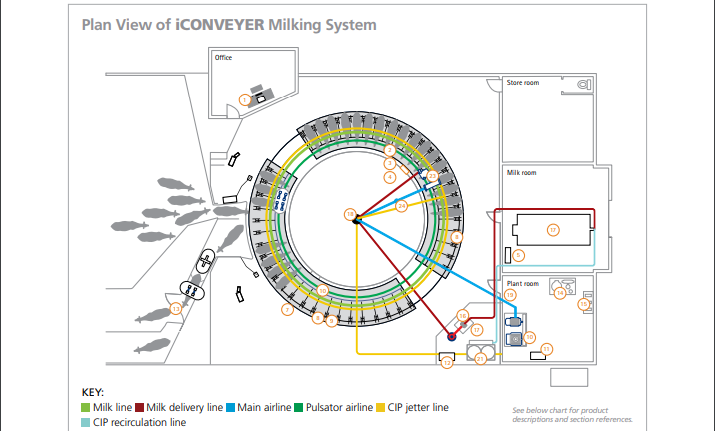

iCONVEYER is a fast and highly efficient lowline rotary milking system.

Milk is transferred gently from the cow to the receiver before being filtered, cooled and stored in the bulk tank. Low operating vacuum levels ensures cow teat end comfort throughout the milking process. Automation and highly intelligent milking equipment designed and developed specifically for rotaries are key features of the system. With the iCONVEYER you can build your system to meet your automation requirements now and into the future. Our experience equipping rotary parlours of all sizes from 28 to 100 milking points ensures that you get the right solution to suit your requirements.

Key Features:

• Modular design with quick and simple installation with minimal onsite fabrication

• Extremely stable vacuum due to milk and air separation in the looped milk lines

• The loop line is cleaned with iNTELJET using powerful slugs of wash water down the milk line for enhanced washing performance and superior hygiene

• Automation options; such as automatic cup removers, drop down, cow restraints and teat spraying, are easily added when required, future proofing your system.