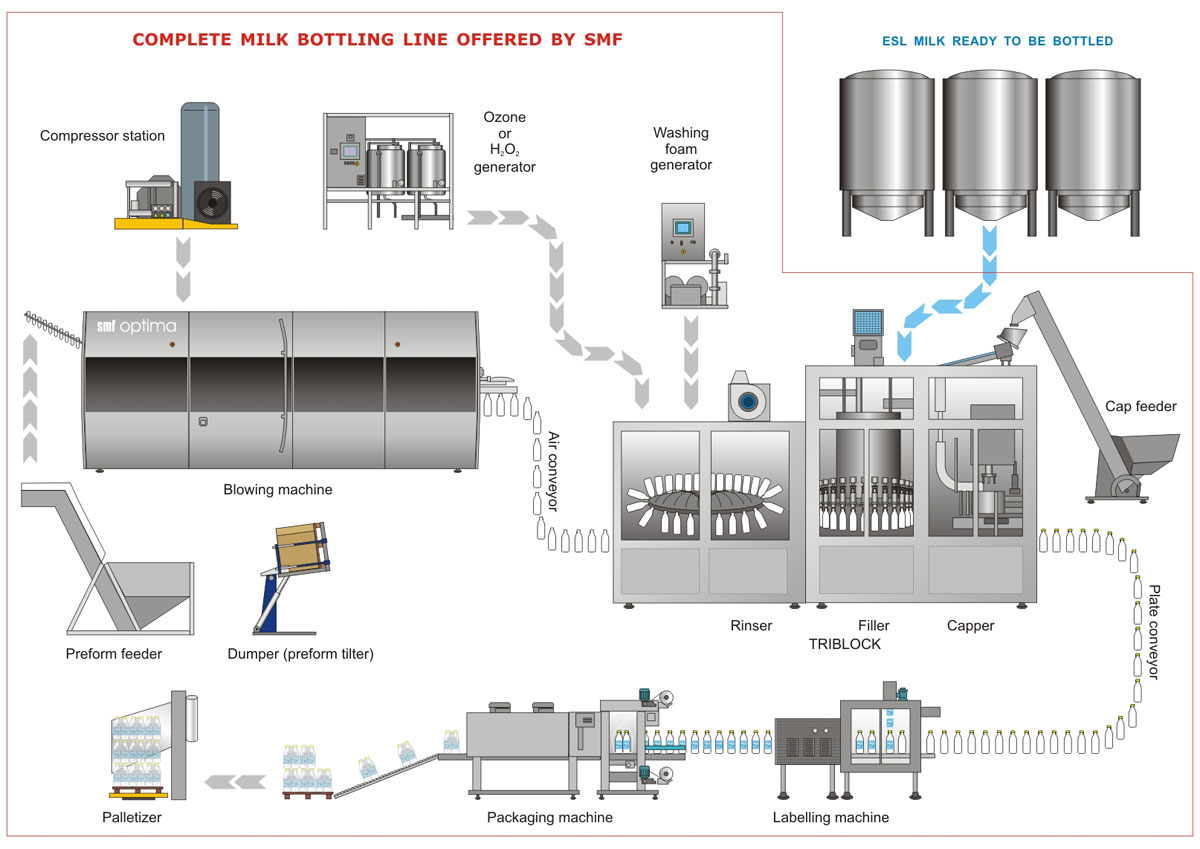

Milk Bottle Plant: In the milk plant where the milk is collected and process, stored, pasteurize packing and ready for supply. The piston RE- filling machine has eight and ten cylinders with control system this system is with double stain steel product tank and a bottle rotation system that makes the new and original flan during the process, the piston filling machines processed by unique design without any leakage, and the filling performance is 1 percent. The body has stainless steel, controlled by the PLA operation clean with GMP standard.

Benefits of the Filling Machines

The automatic filling machines allow flowing products with high viscosity things like milk, paste, and jelly. In the line system, 120 bottles can reach per minute and allows 1000 of bottles to be filled each and every day.

Reliability: hand filling make a variation of the single product, but automatic filling allows for a reliable and consistent for every cycle fill is based on volume, weight, level measurement.

Versatility Operation: Automatic bottle fillers can handle a wide range of container shapes and sizes, these machines can handle multiple products to fill both thin and thick product. Handle a wide range of container size and the shapes, most of the machine to fill both thin and thick liquids.