The machines and equipment easily and effectively used have helped the milk farmers achieve a good standard. There is a great output in milk and its products which is at the same time promising. Machines, like Khoya making machines, have helped the farmers to a greater extent.

The Khoya making machines, automatically prepare Khoya from the milk. The automatic machine will only require the supervision of an individual and takes place in the shortest time possible. Khoya is one of the best deserts in India and Kyoya making machines have reduced the time and manpower injected into the procedure.

Where to get the Khoya making machine

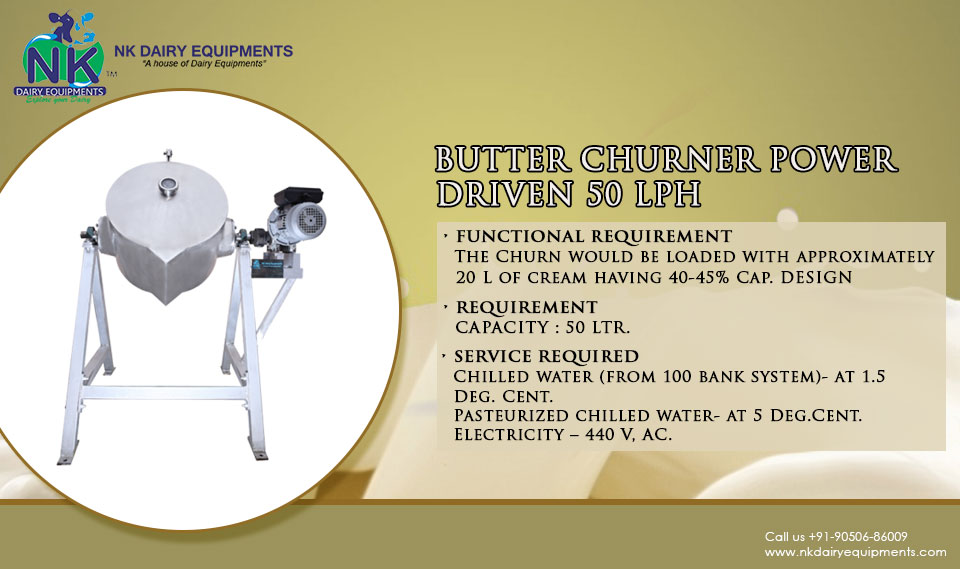

NK dairy equipment is one of the leading manufacturers and suppliers of dairy and milking machines in India. They provide quality machines that are entrusted for long term purposes. They are easily operated, promote hygiene and easily maintained. Various dairy farms have accessed the machines at a lower price and have fully benefited from the new technologies.

The Khoya making machine

Ideally, milk and its products are part of the humans due to their nutritional value. The Khoya making machine can also be used to make different sweets such as Penda, Basundi, Dudhpak, and Barphi. Other uses include;

- Mixing or making ice cream

- Condensing milk

- Roasting

- Mixing of chemicals

- Making herbal products

- Making curd

The machine can be used on gas or fuel and its consumption is optimal. For proper usage, it must be operated by someone trained. Mechanization has made formerly complicated activities easier on the farms and in the dairy industry. Machines and equipment manufacturers like NK dairy equipment specializes in improving and modernizing farm activities. In that way, the products are manufactured with great diligence to preserve the milk and its products and keep up the milk standard. The quality machines include

- Buffalo milking machines

- Cow milking machines

- Mobile milking machines and other dairy products machinery

These machines are manufactured from the best material that is durable and is easily maintained. The same machines when properly used reduce the occurrence of infections that normally spread easily on the farm. Getting the automatic machines will also reduce the time spent and the costs incurred in case labour is used on a large scale.