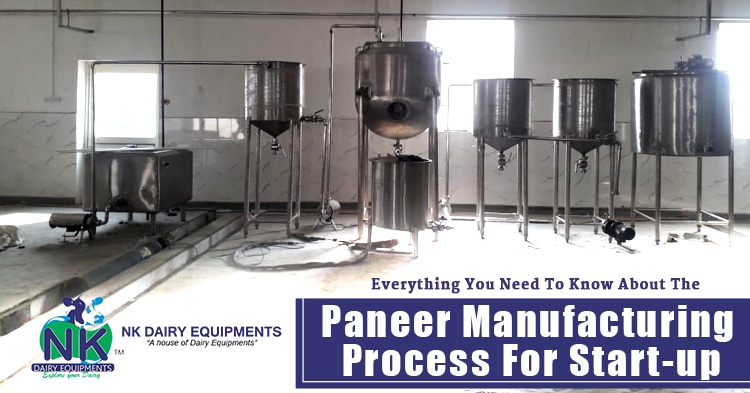

NK Dairy Equipment is the leading company that manufactures easily operated dairy plant machines – including curd-making machines, milk pasteurizer machines, lassi machines, and paneer-making machines. NK technicians carefully design all machines. Without reliable machines, dairy plants may produce large amounts of dairy products.

In this video, NK Dairy Equipment company presents the machines for paneer cutting and paneer pressing. These machines are made from stainless steel. Stainless steel is safe for making canned food because it is hygienic and durable. When it comes to making dairy products, it is essential to maintain hygiene. NK Dairy carefully designed machines that are easy for the operator to operate.

Paneer cutting machines professionally cut the pieces in equal shapes and sizes without losing the product quality. Quality is essential for each product, which makes the product safe for consumption.

Paneer pressing machines put the right pressure on the paneer to achieve the right texture. Pressing machines are easy for an operator to operate. In this video, a person uses a hand to pull the handle to put pressure that converts the paneer into the right texture, making it easy to cut. NK Dairy Equipment manufactures reliable machines that work perfectly for a long time and help to increase paneer production without damaging product quality.

If you want reliable and durable paneer-making machines to establish the plant, contact NK Dairy Equipment.