Paneer which is known as cottage cheese in English is the important ingredient of various kinds of foods of north India. There will be nothing wrong if we will say that most of the north Indian cuisines are incomplete and tasteless without Paneer. This great demand for Paneer can be due to abundant availability of dairies and dairy products and even due to high nutrition value of Paneer.

Even reports have revealed that demand for cheese increases every year by 10-12% not only in India but also in other Asia Pacific countries. There are several reasons for the growing demand of this cottage cheese like its consumption in various cuisines and increasing number of fast food chains that take cheese as an important ingredient in their foods like pizza, pasta in many forms. Moreover, the increasing trend of vegetarians can also be the reason for the growing demand of Paneer.

This is the reason that Production of Paneer is spreading and its manufacturing is getting famous in various parts of the world. With the growing demand for cheese, many avenues are opening in India that is starting Paneer manufacturing for the business purpose from small scales even.

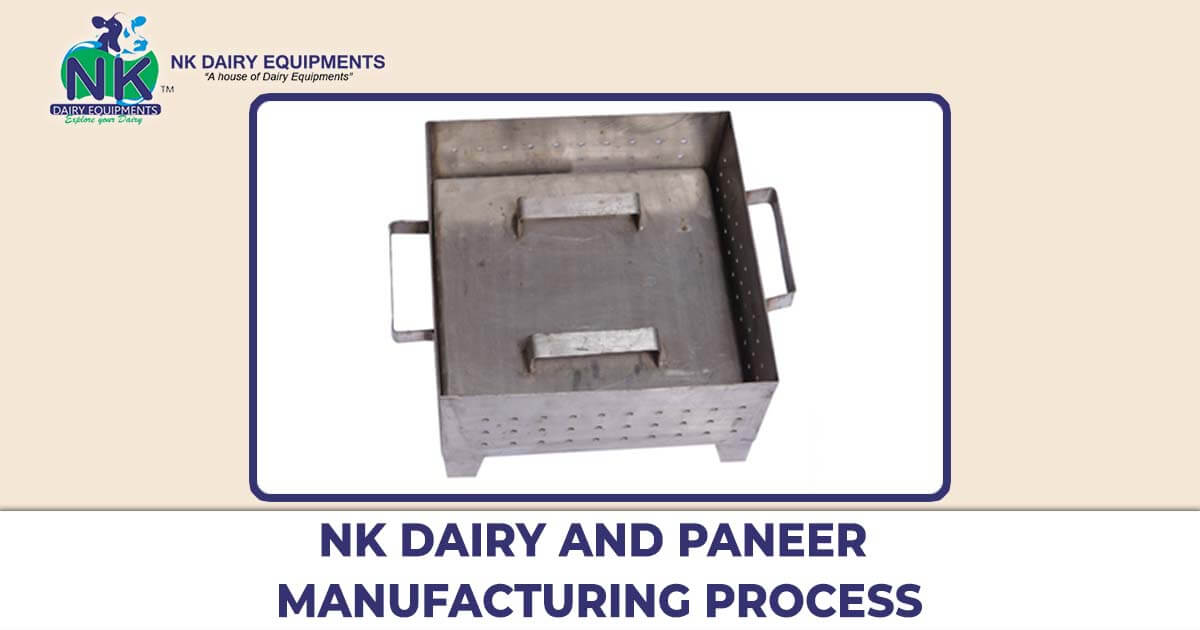

We here at NK dairy provides you with the Paneer making machines like Paneer press so that you could have a high quality of Paneer.

Paneer manufacturing with us

In the Paneer making process high-quality standardized milk is heated to 90 degree Celsius and then cooled down to 80 degree Celsius for coagulation of milk. After the coagulation, the coagulated particles are poured in the Paneer press to drain the whey and separate the Paneer after pressing it.

For the formation of soft textured Paneer it is important to press the Paneer only inadequate way and with adequate pressure otherwise, it could get dry and lose its soft texture. Further, the Paneer is separated and kept in cold water for vacuum sealing and packaging to supply in the market.

We offer Paneer press machines, processing plants from small, medium to large size business units according to requirement. We offer the best quality machines and plant on the basis of individual needs and requirements. We offer Paneer press, Paneer separator, Paneer maker, and Paneer cold room etc for the perfect and hygienic manufacturing of premium quality Paneer.