The global Cheese market Is increasing

Under the given stats, it is seen that the global cheese market is expected to grow around $105.9 billion by 2026. All the effective working and how things are managed play a crucial role in managing the sales and taking the cheese industry to the next level. Most importantly, it’s all about managing the necessary demand and getting the production scale of the business taken to the next level. For the dairy business owner who has the necessary Milk Processing Equipment, it’s ideal to make it all manageable and seek the necessary results accordingly. Similarly, the cheese packaging business needs to make it stand out by all means.

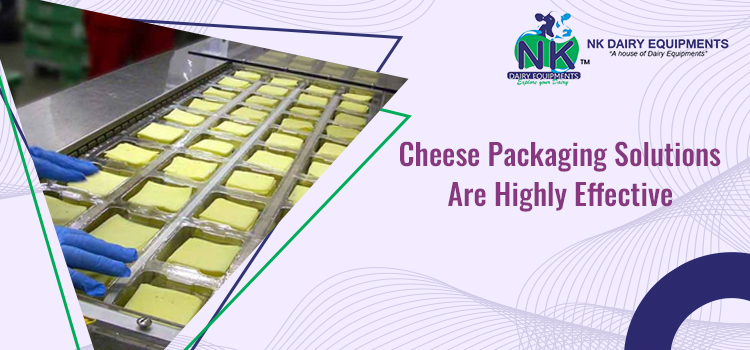

Reap all the necessary benefits of flexible packaging

For the cheese brand and packagers, the ideal part is to have added value and offer the necessary convenience to get everything managed precisely. Being flexible with packing methods allows necessary products to have a proper demand-supply chain. There won’t be any damage, whether your dairy business has cheese packaging or khoya Making Machine.

Additionally, the cheese is sold in different packets, which allows the customers to seek the necessary product depending on what they wish for. Moreover, it allows the business to manage all things with ease, and necessary results are obtained to make the dairy business seek the best results. The packaging solution’s effectiveness plays an all-important consideration in keeping up with the transmission rate and allows the cheese moisture to not get affected until it’s not opened.

Increasing sustainability in cheese packaging

One of the imperative parts is taking up the Paneer Cutting Machine and packaging machines to a sustainable level to ensure effectiveness is higher in every case. Seeking the best of methods from start to end makes a lot of difference and allows precision in everything. Effective packaging plays a major role in getting everything done effectively. The right kind of packaging plays an imperative part in ensuring attributes and features are in the right space.

Did you know?

Choosing an approach of compostable and recyclable materials makes a difference in getting product value higher. No matter which material, the ideal approach is to reuse and repurpose everything to ensure the product is in the right space.

How does it benefit the consumers?

Consumers highly prefer those products packaged with perfection and those that offer high shelf life. The option of zippers and sliders allows to make it all efficient and let everything be managed in a safe space. This is why the top-rated dairy business owners make the most in terms of functionality and every step to be done with caution to ensure desired results are obtained without any problem.