पाइपलाइन मिल्किंग पार्लर क्या है ?

पाइपलाइन मिल्किंग पार्लर यह एक ऐसी तकनीक या प्रणाली है जिसकी सहायता से गायों की थानों में से दूध को पाइप लाइन द्वारा स्वचालित तरीके से निकाला जाता है | यह एक तरह की विशेष मशीन या टेक्नोलॉजी है , जिससे सहायता से व्यक्ति को हाथ का उपयोग कम होता है और गाय की थानों दूध से दूध भी निकाल लिए जाता है | प्रत्येक गाय से एक-एक करके दूध को निकालने के बजाए, मशीन सीधा ही गाय की थानों में जाकर जुड़ जाती है और लम्बे पाइप की सहायता से दूध को निकाल कर एकत्रित किया जाता है | इस मशीन की वजह से समय भी कम लगता है और यह भी सुनिश्चित होता है की दूध देने वाला क्षेत्र गाय के लिए स्वच्छ और स्वस्थ है |

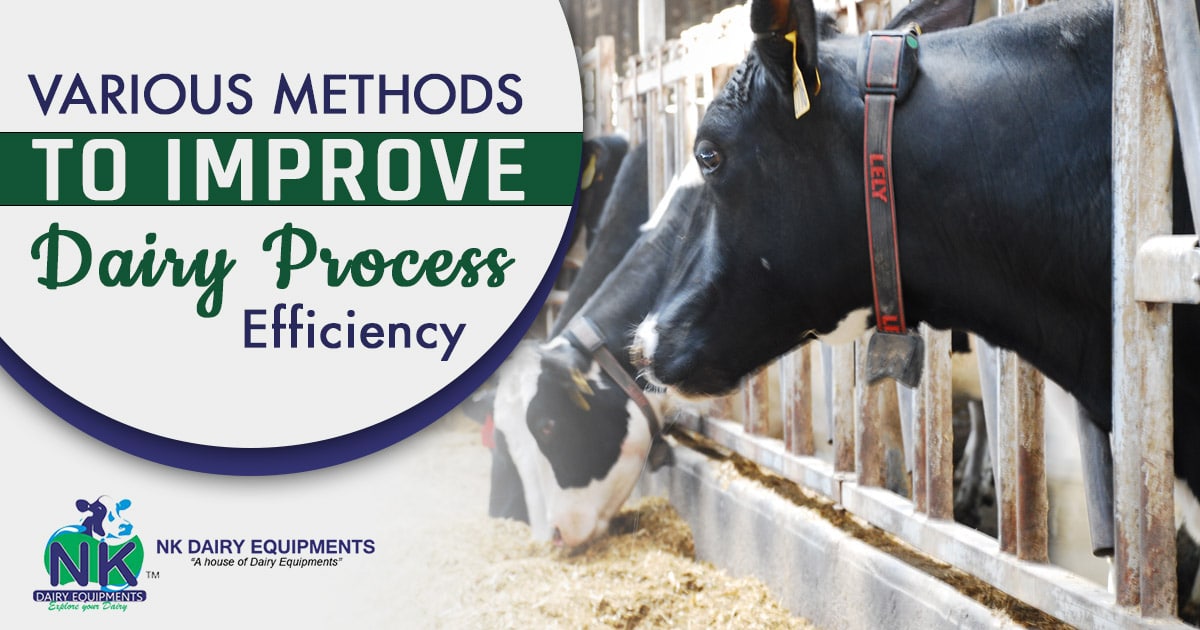

गाय का पार्लर में प्रवेश :- गाय को पार्लर में एकत्रित किया जाता है , इस क्षेत्र में गाय को आरामदायक स्थिति में रखा जाता है, जिससे दूध निकलने में आसानी होती है |

स्वचालित इकाइयों से दूध निकालना :- जब सभी गाय अपनी जगह में आ जाती है , तो स्वचालित तरीके से दूध देने वाली इकाइयां गाय की थानों में जाकर जुड़ जाती है |

गाय की थानों से दूध निकालना :- यह इकाइयां वैक्यूम के दबाव का उपयोग करके गाय की थानों से दूध निकालने का काम करती है |

पाइपलाइन विधि :- दूध पाइपों की सहायता से एक क्षेत्र में प्रवाहित होता है | इस प्रणाली को दूध को दूषित होने से रोकने के लिए डिज़ाइन किया गया है |

नियंत्रण और देखरेख :- इस प्रक्रिया को सम्पूर्ण देखरेख और नियंत्रण कंप्यूटर तकनीक द्वारा किया जाता है और इस बात का भी ध्यान रखा जाता है की सभी गाय से कुशलतापूर्वक दूध निकालने की प्रक्रिया की जाए और दूध को सही तरीके से एक प्रणाली में एकत्रित किया जाए |

पाइपलाइन मिल्किंग पार्लर लाभ क्या है?

कम समय में काम होना :- पहले क्या होता था कि किसान को अपने हाथों की सहायता से एक-एक करके गाय की थानों से दूध निकालना पड़ता था, जिससे समय बहुत लगता था और मुश्किलों का सामना भी करना पड़ता था | पर पाइपलाइन मिल्किंग पार्लर की सहायता से यह काम बहुत आसान हो गया है और समय की भी बचत होती है |

गाय को आरामदेह देना:- गाय की थानों से धीरे- धीरे और कुशलतापूर्वक क्रिया से दूध निकला जाता है, जिसकी वजह से गाय आरामदायक और स्वस्थ महसूस करती है |

लेबर का उपयोग कम होना :- इस मशीन की वजह से डेयरी फार्मिंग लेबर का उपयोग से राहत मिली है, जिससे अन्य कृषि कामों के लिए समय भी बच जाता है |

स्वच्छता में उन्नति होना :- पाइपलाइन पार्लर दूध देने वाले क्षेत्र को साफ़ और स्वच्छ रखते है, इसकी वजह से मानव संपर्क भी कम होता है और दूध को दुषित होने से रोका जाता है |

डेयरी फार्मिंग को बढ़ाने में सहायक है:- यह किसानो की डेयरी फार्मिंग के व्यवसाय को बढ़ाने में भी सहायक है |

अगर आपको इससे जुड़ी कोई भी सलाह लेना चाहते हो तो आप एन.के.डेयरी इक्विपमेंट से ले सकते है, इनके पास डेयरी फार्मिंग से जुड़ी हर तरह के इक्विपमेंट मौजूद है |