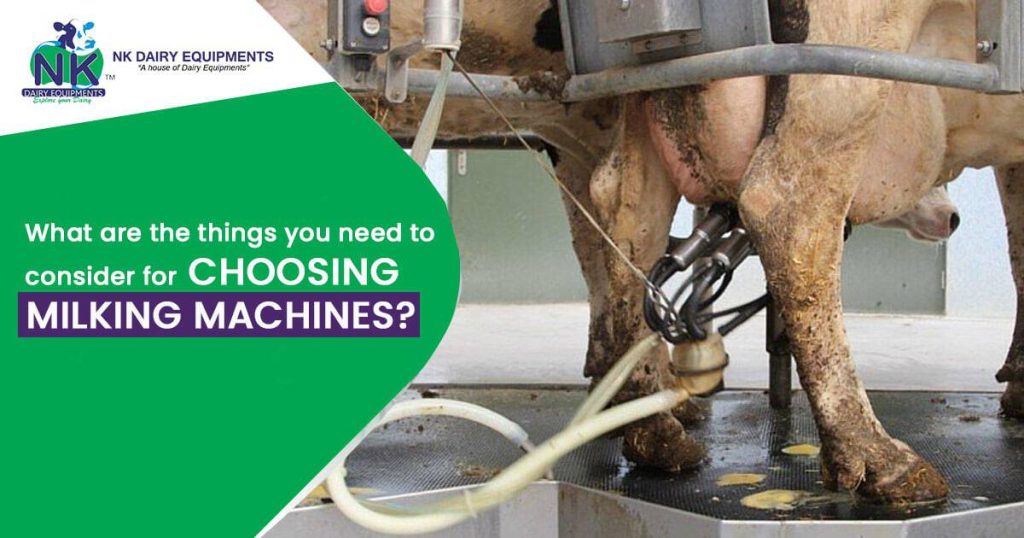

What are the things you need to consider for choosing milking machines?

How to use a milking machine To start the milking machine you need to start it and use the valve on the claw to seal the vacuum till the time it is built to 15 psi. The patients need to use the best quality of dairy machinery. After that, you need to get down behind the cow and then the valve is released and the teat cup is put on the teat which causes the vacuum to release till the time the teat cup is sealed. After that, the cups are put on the teats and the vacuum will hold them in place to remove the milk. The milk flow and udder are watched until the time enough milk is taken. The valves are used to seal the vacuum and all the cups are removed with ease in one go. After that vacuum is released and the machine is turned off. How to select a milking machine? Milking machines are costlier. Just make sure to get in touch with the experts and they can suggest to you better on what type or model you need to get. With the expert’s understanding, you will be able to compare the different options available in the market. Given below are some of the things which you need to consider: ● Hygiene These machines can clean quickly and easily after the milking is done. ● Durability and material quality The machine needs to be of the best quality so that they can last for a long time and your business can be managed effectively. ● Moving parts and spare parts Generally moving parts are not able to last for a long time. Additionally, you can get spare parts. You can replace the individual items which can be worn easily. If you are not sure what to use and how you can manage the machinery then get in touch with experts. ● Noise levels With the milking machines, the electric motors are used on the motor vacuum pump. It means there is a need for electricity and it makes loud noises. Not every model is the same so you need to use the machinery effectively. ● Types of vacuum pump Different system models come with different pumps. It is important the pump which is used should take out the required amount from the vacuum. The ideal choice is to get in touch with the manufacturer. Keep in mind cheap options are not going to work reliably and they fail. ● Warranty You should consider the warranty period to make sure the machinery you are using is effective for a longer time. Ask the manufacturer whether it will cover all the parts or not.

Everything about different Machinery and Equipment Used in Dairy Farming

Dairy farming equipment includes pasteurizers, vaccination buckets, automatic milkers, and more. The dairy farm’s main function is milk production. It is a capital intensive venture which needs long term investment and proper management. Farms generally stock the same breed with a history of high milk production. How to select Dairy Farming Equipment? The number of cattle will determine the milking system. Selecting the best quality dairy machinery is extremely important for your business to grow. Equipment which cut down the operational cost, labor, and time should be considered. Look for options like space, range of features, automated, quicker output, or manual. You need to make sure the equipment has spare parts for easy replacement. From pasteurization to storage everything needs to be done correctly. Dairy Farming Equipment Basic milk processing equipment is pasteurizers, separators, homogenizers, and tanks. The primary equipment is milking machines. There are different designs, specifications, and functionality. Pasteurizers The milk harvested from cattle contains bacteria or harmful agents. The milk heating process is to neutralize the bacterial presence. The milk is heated for 16 seconds at 72 degrees. Separator This machine is used to separate cream and skimmed milk. Used to produce milk products and all these components are made from plastic, aluminum, and stainless steel. Homogenizers and Tanks The tanks are used for storing the products. The homogenizers are machinery that separates the immiscible liquids into the emulsion. More equipment includes housing and refrigeration. Machinery and Equipment for Dairy Farm The machinery type depends on the operation size. If you are going to start with a small setup then you need to make the changes accordingly and get the machinery accordingly. The machinery can be manual, automated, and semi-automated. Temperature control is important and for that utility vehicle is needed for supplies. For running a smaller farm, then feed grinder, loader tractor, and milking cans are needed Farm Equipment Fodder truck Tractor implements Fodder compacting press Fodder block machine Administrative office equipment Milking equipment Mud pump Baler Pressure washer Fodder mill Generator tractor Tanks Moveable fence Fodder harvester reapers Feed basket Loader tractor Feed grinder Milk cans Borewell with motor Electric fencing Semen container Accessories Types of Milking Process Different types of machinery and equipment are there to have the profit you are looking for. Common processes are fully automated, hand milking, and robotic milking. There is the pipeline included which makes the entire functioning of the milking process smoother and the vacuum bucket milking system is effective. Different Types of Milking Processes Hand milking Fully automated robotic milking Rotary parlors Automated milker take-off system Parallel parlors Milking pipeline system Vacuum bucket milking system The Fully Automated Robotic System With an automotive milking system, the working of the entire milking process will be done smoothly. This is great for increasing production and helps your business to get the benefits they are looking for.

What are the various methods to improve Dairy Process Efficiency

Here, at our NK dairy Equipments, you will find the quality products and we offer milk plant for your dairy business. We also provide you dairy process efficiency and mechanical processes directly in order to increase process performance, and are ready for disruption utilizing Industry 4.0 technology. Here you can see the main processes adding importance to raw milk: That of these procedures needs machines and facilities that are labor expensive which both include a certain sort of packing line to stock which plans for shipping the finished product. Through the method of processing raw milk products provides the possibility of enhancing process performance with our Analytics software such as Worximity. Unloading whole milk When raw milk is obtained from the dairy, any tanker truck is usually removed from the carrier. The unloading cycle requires a generator, usually a constructive rubber device. Upon unloading the car is sprayed into the nozzle installed up to the top of the tank by pumping hot water and sanitizing water which directs water on the entire inner side of the tank. As the trucks from farms that take raw milk are enclosed and not cooled, unloading is important when necessary. Despite product degradation, you can not get trucks lined up in the yard for longer hours. These trucks appear to be big, and any prolonged pause in waste raw materials will contribute to substantial costs. For vehicles to reach the plant and liquid milk to become tanks or processing processes, the reliability of the truck loading bay is important. Clarification and cooling of milk Raw milk is also sent to eliminate particulate contaminants via a centrifuge for Clarification to be cooled by a heat exchanger as it is collected or eventually refined. The manufacturing of milk goods also faces one challenge: heat exchangers are also foul. The energy to transfer liquid through the heat exchanger rises, flow declines prolongs the cycle period, eliminates operations, and lowers the performance of the device as the heat exchanger is squeezed. It ensures the heat exchanger systems will become causes of bottlenecks as they have to be washed due to sluggish processings or downtimes. Standardization The milk is typically ‘standardized’ to normalize the fat and nonfat components as required in order to better refine the finished product. Milk is typically divided by a centrifugal separator into skims and cream goods. The milk should be measured and the fat is then separated to accomplish the intended goal, and the milk can be divided into the two elements. Pasteurization, Steam Generation & Co-Generation ‘Pasteurized’ is used as a heat treatment method for the bulk of milk items. Pumps are used to transfer the commodity and heat exchangers are used again in this processing step. Certain other processes to improve efficiency. Homogenization Cooking and Fermentation Mechanical Work Freezing, Hardening & Evaporation Packaging Cleaning

Dairy Processing and Packaging Solutions & Machines

We are offering a range of Pre and Post dairy processing and packaging machines equipment as well as providing a full system solution. They may also be customized to specific product lines and installed.

What is milk pasteurization and How Milk Pasteurization is helpful to keep milk fresh & healthy?

Taking this critical recommendation into consideration, the Milk Pasteurization Machine Manufacturers reveals that UHT Milk Processing Equipment is beneficial to use to ensure optimum pasteurization process.

Why is Turmeric Milk Essential in Everyday Diet?

Not everyone is aware of the benefits of having turmeric milk. This blog is specially written for those, who want to treat certain health issues by consuming turmeric milk. So, you have to read it properly at the end to get detailed information about turmeric milk. These days, several farmers are running dairy plants businesses due to the high demand for milk products. You can simply produce tons of milk and other dairy products with the help of a milk plant. These milk plants are valuable to produce quality products so that everyone can enjoy them properly. In this blog, we are going to tell you the benefits of turmeric in everyday diet. Turmeric offers you antibiotic effects and includes a chemical compound named as curcumin. This compound has the capacity of being ingested into the fat and tissues of our body. When you mix it into the milk, it provides an ideal medium in which curcumin passes easily to the fats and tissues, allowing its absorption easier. By adding turmeric into milk, you can treat several health problems. Here are some of the health benefits of consuming Turmeric Milk every day: Purify the Blood One of the key advantages of turmeric milk is the purification of the body. This milk is helpful to boost the circulation of the blood as well as cleanse the blood vessels. Prevents a Disease Curcumin in turmeric has been shown to be effective in destroying cancer cells and reducing their capacity to propagate and destroy DNA. Turmeric milk can help prevent cancer growth in the early stages on a regular basis. Promotes digestion Anti-inflammatory properties present in turmeric milk help to manage digestive problems by promoting digestion, preventing stomach ulcers, and diarrhea. You can also get rid of heartburn, Bloat, nausea, and other stomach diseases. Combat respiratory issues You can get rid of any pathogens or infectious agents from the respiratory system with the help of turmeric milk. This is an Antimicrobial that prevents bacterial and viral pathogens. This is an important treatment for allergies, bronchitis, which also offers immediate relief from sinus lung inflammation. Aids Lack of Weight Yeah, turmeric milk helps to lose weight. According to the best dietitian in Ludhiana, turmeric contains dietary fiber, and these are valuable to prevent weight gain, also you can get rid of extra fat deposited in your body. Promoting Good Sleep Promoting healthy sleep is another well-known safety advantage of consuming turmeric milk every day. It creates amino acid-tryptophan and you must consume it every night before bed makes you relax, settle the mood, and thus encourages undisturbed sleep all night. You can also get rid of cold and cough by consuming turmeric milk.

Benefits of Skimmed Milk

Looking for a milk option which is low-fat and low-calorie. In that case, skim milk is the best option. Skim milk demand has increased all over the world because of the way it is made and the various benefits it provides. Read the given topic, the understand the benefits of skimmed milk. Introduction Skimmed milk is a low-calorie and low-fat version of traditional full-fat milk. Many people think that the nutrients are taken away from skimmed milk. But, this is not true. The skin milk is prepared with the centrifugal separation process in which the fat molecules are taken out of the milk. The benefits it provides have increased its demand all over the world. This is the reason, more dairy plants are preparing skim milk to fulfill the increased demand. How skin milk is beneficial? Given below are some of the topmost benefits of skin milk to consume it daily: Enriched with protein Skim milk is loaded with 9 essential amino acids which helps the muscles to become strong. Consumption of skim milk will build muscles quickly and also help them to maintain it. Moreover, the protein it contains is very easy to digest. So, consumption of skim milk is beneficial for your overall health and it is safe as it is loaded with essential proteins. Great source of Calcium Milk is a great source of calcium and that goes for the skim milk. But, skim milk provides more calcium as compared to other whole milk variants. Our body contains various tissues which need calcium to function. Consumption of one glass skim milk will provide you 30 percent of calcium your body needs. Helps in weight loss Skimmed milk is prepared by skimming the cream which has fat and this makes it low-fat. Due to the low-fat content, it helps the person to prevent weight gains and gives the same benefit as the whole milk. So, if you are looking for a weight loss option then skimmed milk. Enriched in Minerals Skimmed milk is loaded with essential minerals like phosphorus, magnesium, zinc, potassium, and selenium. With these minerals, it improves the blood pressure and ensures the heart function is proper. Additionally, the calcium presence in the milk is great to build strong teeth and bones. Low in Cholesterol Increased levels of cholesterol can lead to heart issues. If you are one of them who is facing issues to maintain the cholesterol level, then you should switch to the option of skim milk. Important Note Skim milk is not safe for the consumption of people under the age of 2 because the fat content is extremely low. Infants need more fat which they cannot get from skim milk. If you are planning to prepare the skim milk at your dairy plant, then get the machinery and equipment from Nkdairy.

Ghee or Oil Which is better for body?

One of the staple parts of the Indian cuisine is the addition of ghee. Some people prefer to use refined oil. But, how do you know which option is best among both these options? In this guide, we will share the difference between ghee and oil, so that you can choose which one is best for your health. Introduction Ghee is the traditional form of clarified butter and it is a source of fat which is found in the Indian kitchen for cooking meals in winters. But, now as people are more focused on their health so they cut down the ghee consumption. To do so, they prefer the option of refined oils in the kitchen. When you are looking to buy the ghee, make sure to get from the best brand. At the best ghee plant, the entire process of making ghee is done in the right manner. Is refined oil beneficial? Refined oil is obtained by treating natural oils with different chemicals and this makes the oil unhealthy for consumption. Chemicals that are used in the refinement process will leave adverse effects on health like the liver, respiratory system, and skin. Moreover, it is also linked to other health problems like diabetes, cancer, kidney, and stroke problems. On the other hand, ghee is beneficial for health and it provides strength, vitality, and vigor to the body. Given below are some of the health benefits of ghee: Ghee is loaded with conjugated linoleic acid which is omega-6 fatty acid type. It is extremely beneficial as it helps to burn the fat and keep your weight normal. Ghee is loaded with essential fat and MFA in high amounts which helps to keep the cholesterol level in the right place by reducing the bad cholesterol and increasing the good cholesterol level. At our dairy plant, we make sure to follow the entire process of ghee making with proper hygiene and keep up with the quality. Ghee includes fatty acid in medium-chain and they are processed and absorbed by the liver and burned which takes the form of energy. If you are an athlete, then the consumption of ghee is highly beneficial. It also helps you live an active life or someone who might feel lethargic all day long. Ghee is loaded with Vitamin E & D, butyric acid, and detoxification properties which helps to increase the T-cell production. This is great for balancing the hormones and keeping the metabolism strong. By doing so, this will help your body to stay strong. Ghee is great for digestion purposes and it decreases inflammation. It helps you stay healthy and keeps the digestive tract in the right order. Ghee contains high levels of Vitamin K2 and it helps to absorb calcium which promotes strong bones and teeth.

Water Management in Dairy Industry

For the business, it is extremely essential to make sure every step is done in the right order. It is essential to manage the water and make sure every area has enough water flow. In the dairy industry, it is extremely essential to follow water management. In this guide, we are going to mention water management. Introduction The dairy plants all over the world use water daily. The water is evaporated which is around 20 lakh liters every day. In dairy plants, every day the water is used for different processes. It is important to follow the right water management practices in dairy processing. The dairy processors need to conserve water necessities and reduce the water consumption or choose the method of recycling water without compromising with the product quality and hygiene factor. You need to choose the best dairy machinery which helps you to manage the entire process in the right manner. Water use in different Dairy sectors For the food preparation, cleaning purpose, and other technical issues water is used. It includes cleaning equipment, dissolution of ingredients, product transportation, and water present in the final product. The process of water needs to meet the quality of drinking water. Cooling water is used to remove the heat from products and streams. It is essential to cool milk at the right temperature. For stream production, boiler feed water is used. The main requirements are low air, hardness, and carbon dioxide content. What about the water wastage control? For the effective water control program, it is important to have the right water metering facilities. This should be around a meter at each entry point. Investing in such meters is great for the dairy business. Some of the ways, in which water wastage can be reduced: Manual cleaning: Where possible, check the cleaning practices and choose the dry cleaning method. To clean the surface you should use the high-pressure low volume cleaners Use automatic shut-off nozzles on all water hoses. Before you clean them, make sure to soak all the equipment and tools. Avoid using water hoses as brooms CIP systems Reuse CIP solutions correctly Reuse final rinse water as pre-rinse for the next CIP cycle. For efficient CIP operation, Review regularly timers and settings Processing Optimize process schedules like preventing pasteurizers for water circulation and it reduces the wastage. To reduce cleaning frequency use continuous processes Recirculation of pump sealing water and homogenizer If the water is reused then it needs to be safe and it should not compromise with the product quality. Any containment in the product will affect the consumer’s health. Make sure, everything is monitored and tested continuously to ensure product quality is the best. If you are looking for quality machinery then contact our team for detailed information.

How is Plant based Dairy Changing the Manufacturing Business?

Milk and milk-based products are in high demand all over the world. With time, it has made it possible to use different products. One of them is a plant-based dairy product that has changed the dairy manufacturing business. Read the given topic, to understand how plant-based dairy is beneficial. Demand for Plant-based dairy products Milk is in high-demand all over the world and it comes in different options like skim and standard milk. Consumers are more interested in having the best milk options to add in the different food products like soy, oat, or nuts. One of the studies has shown that the demand for plant-based food products increased in 2018 and still, these numbers are rising continuously. With time, the consumers prefer to use the products which are beneficial to their health. If you are looking for options with fewer calories and less amount of sugar & carbohydrates, milk alternatives are a perfect choice. Another reason, consumers are using milk-based products because of allergies. The option of plant-based milk will help consumers to lower the environmental footprint. Due to taste preferences, people are also choosing plant-based milk products. If you are planning to set-up your dairy plant then you should get in touch with our team and they will give you the quality machinery & tools. How the plant-based revolution is changing manufacturing? In the past, many dairy companies have made an effort to use alternative milk types. At the dairy plants, some of the farmers focus on getting plant-based beverages that come from soy or almond. With time, the demand has increased which has benefited the dairy business owner in different ways. To make sure it is done correctly, you need to understand the complexities. To fulfill consumer needs, it is essential to focus on traceability and go through every stage. For consumer safety, it is essential to keep up with regulatory compliance. The final product which is being produced should be safe for consumption and this is done when the production process is in full control. To get the best recipe, a lot of trial and error needs to be done. There is no point in compromising with the quality, taste, or flavor. Perfect solution This is where plant-based dairy products are fruitful choices and it helps your business to stay alive. The dairy manufacturers need to focus on the growing trends and then make changes accordingly in their business. Moreover, the use of the latest and right technology will help you go a long way. So, this is a great way to increase business efficiency and reduce costs. We are here to help your business run as per the industry standards and help you to do well. If you are looking for quality machinery contact our team for further details.