Everyone consumes milk every day because it gives protein which is useful for a healthy lifestyle. Milk is also useful to produce many types of products such as cheese, curd, khoya, and other things, for example, sweets. People nowadays lean toward dairy farming because it is a business which gives more profit because milk is useful to produce many types of dairy products. If you are thinking to plant milk processing unit then you should some tips keep in mind for better functioning such as proper installation, periodic inspection, waste management plan, and cleaning of plant and types of equipment.

Tips to ensure the better functioning of the milk processing unit

Proper installation

Proper installation of a milk processing unit leads to better functioning of your plant and processing unit. You must consult experts they will guide you for proper installation of the plant in order to get better results. In this way, they will also guide you about the maintenance of this milk processing plant.

Periodic inspection

Make sure you should go for periodic inspection in order to maximize the functioning of the dairy types of equipment. You must call experts and inspectors for inspection because it will help you to grow your dairy farming business.

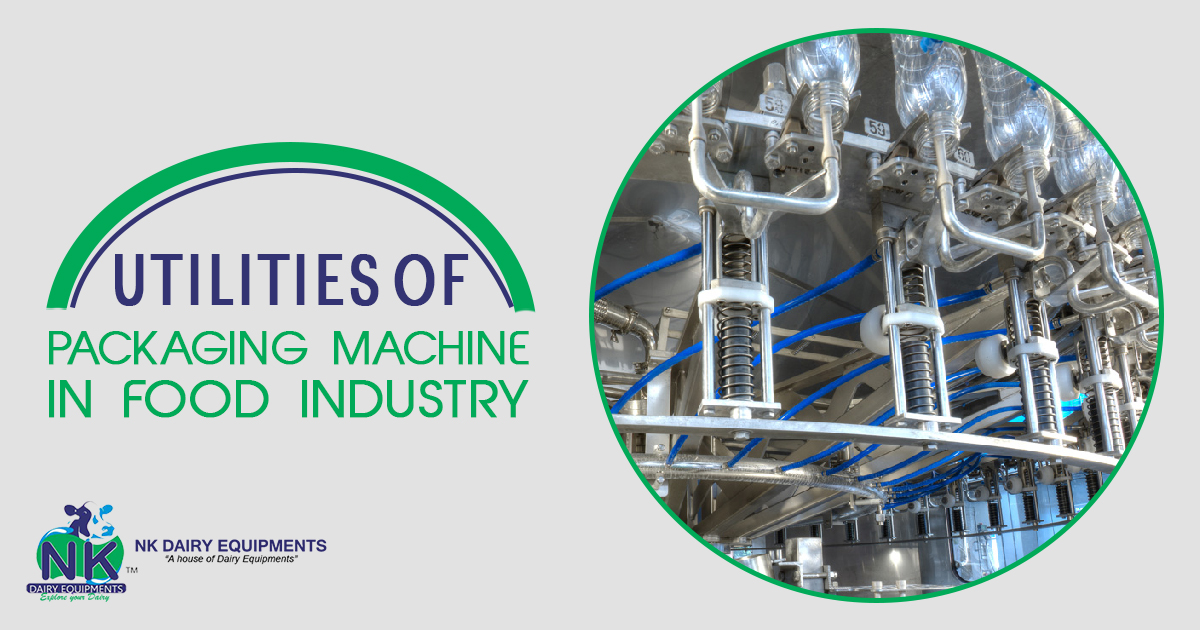

Cleaning of plant and types of equipment

Cleaning process plays an imperative role in milk processing unit because if you use the unclean dairy machine then it will lead to many health problems. You must clean your milk processing units daily or twice a day for better functioning. Make sure do not store milk and cheese for many days in dairy utensils because it will the proteins present in dairy products. There are some basic steps in order to clean milk processing units such as as-:

- Use boiled water with the goal to kill germs and bacteria that are present in storage units.

- You should use gentle utensil cleanser in order to clean them properly. Avoid using chemicals because it cannot clean your units properly.

- At last, you should wash them with cold water and leave them for drying.

Disinfection of milk processing unit

This process is useful to remove infections from the milk processing units. There are three types of methods such as steam, hot water, and detergent or disinfectants. These all the methods are necessary for deep cleaning of milk processing units because these can lead to better functioning for milk processing units.