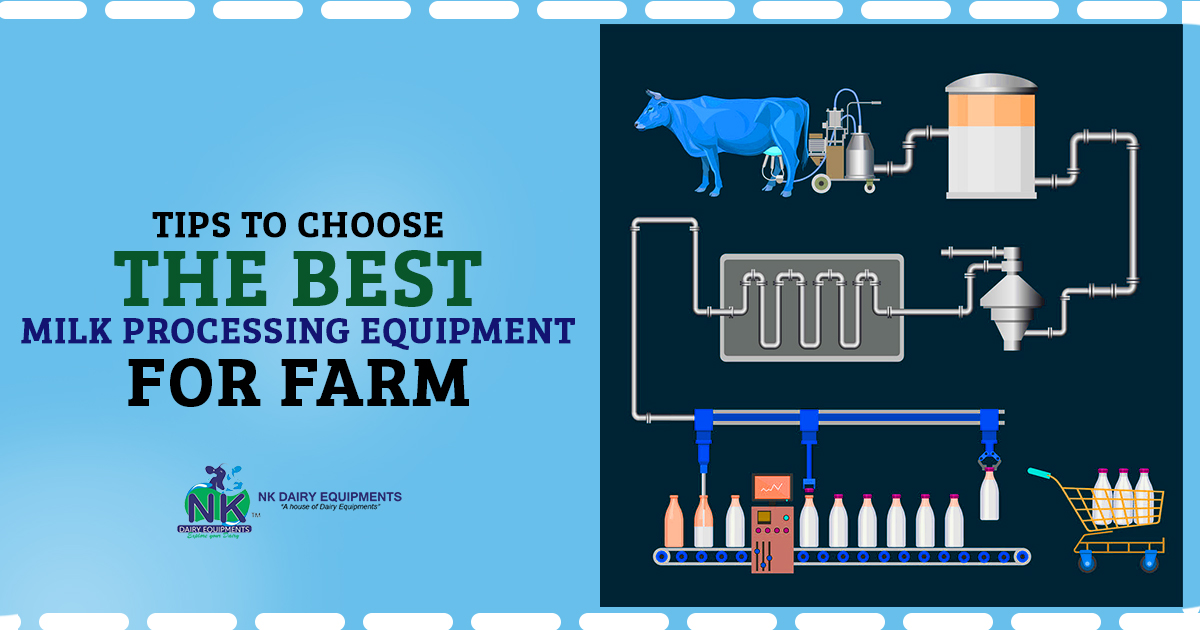

Dairy equipments are necessary for every milk processing unit because they play an important role. You must choose the best quality dairy products with the goal for better functioning. Many farmers choose cheaper products because they want to save their money but it can increase the risk of serious problems. For example, cheaper products are not useful to store milk for the long run because these can cause many health conditions. There are different types of equipment that are explained as below-:

Storage units

Storage units include large tanks and utensils which are useful to store milk for the long run. These storage units are also useful to move milk from one place to other places. You should talk to the manufacturer about the type and size of the storage unit because these are available in different sizes and styles. You should choose the best products according to your choice and needs. But you need to clean them regularly with the gentle cleanser and soap in order to protect milk from harmful germs and bacteria.

Separators

These types of equipment such as milk separator are useful to separate the cream from the milk. Farmers uses these units for raw or processed milk in order for cream separation. This unit is additionally known as a cream separator because it is only used for this process. After the separation of cream, he will prepare milk for delivery and making sweets and khoya. Majority of farmers do not use this unit because they want to deliver thick and high-density milk to other people.

Homogenizer

This is the unit which is useful to check whether milk needs again cream separation process or not. This is totally essential and cost-effective product because it is useful to save your money for the long run.

Milk Reception units

This is the types of equipment which is used to processed milk. Farmers use this milk reception unit for better and effective functioning. This is the unit which worked too fastly as compared to other units because it is too difficult to process milk in large quantity by hands. So, that’s why farmers use this for milk processing.

There are many other types of equipment that are necessary for dairy farming you must talk to your manufacturers. They will guide you and tell about the usage of these products and units. Moreover, these units are designed with total protection and high quality.