With time various things are noticed be it about the technology or the way different things are considered. Inventive methods are indeed making a difference in the way work is done. Especially, the dairy sector is making its way to that change which can benefit the dairy business owners to a great extent. In this article, the talk is regarding the milk overhead tank and rotary milking system.

Milk overhead tank

The use of a Milk Overhead Tank of around 100 LTR to 2000 LTR is benefiting the dairy business owners in all ways. Such a storage solution is effective in every sense as to store the milk and make sure everything is well-managed the way it’s needed. It’s one of those choices which is designed in a way that the maximum amount of milk can be stored. Well! This is the reason the dairy owners are using it to the fullest in making the dairy business stand apart from the rest.

Most intriguing features of milk overhead tank

-

Stainless Steel

It’s the amazing features of stainless steel that combines the property of quality and makes it everlasting in all ways. The steel has those amazing features which are difficult to get through aluminum. Some of them are:

-

There won’t be a tint of corrosion

-

Facilities provided through the tank

-

Its reusability features are amazing which means the cost will be saved to a great extent

-

Insulated interior

The overhead tank is not just to ensure the flow goes easily even if the material will be supported inside it right away. The maintenance will be much easier. So, if you are looking for something in terms of hygiene then this is best.

Well! The features are endless and it’s bound to get better each time. So, such an option that is available in the market should be opted for in the dairy farm.

Rotary Milking Systems

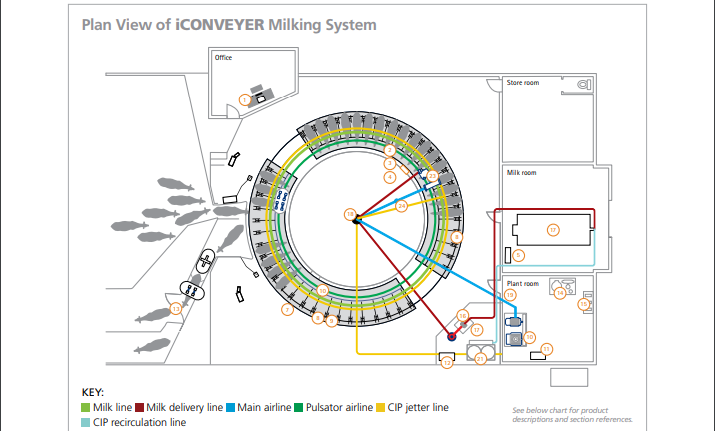

If the operating times have to be short then what should be the preference? Well! For that, the Rotary Milking Systems works the best and its high performance makes it a great choice in multiple ways. Be it the seamless working or the function of an automated system the desired results are bound to be achieved with this. Especially during the peak operating times, their installation is worthwhile in the dairy plant in many ways.

Customized system of Rotary Milking

Every customer’s requirements are different and they know what will be worth for their business. So it’s better to reach the team of dairy equipment & machinery manufacturers who can address all that needs. The rotary system will be given to you under the budget and by making sure it has all sorts of essential features which you are looking for.

Single Beam Pedestal Roller System

As the name suggests, designing comes with a single beam and there is the use of different operations for the same which makes it a relatively low-cost choice. Lubrication is one of the important parts to make sure the work is as smooth as possible. In this type of rotary system, the lubrication is automated which allows everything to be less messy and the working will be for a long time. Being a modular system its demand is rapidly increasing among dairy business owners.

Do you wish to have these?

It’s better to get in touch with the best and experienced team of dairy manufacturers like Nk Dairy Equipments.